Elliot and I tested the polished panels weekend before last.

They functioned, but our calorimetric tests were a miserable failure. We conclude that we can focus the rays but it is very hard to get them into the target. We can probably toast bread well, because it is a nice, flat, target. However, attempting to heat our jar of water was very ineffective.

However, we are not giving up. Rather, we are now going to investigate using a large Fresnel lens, which Elliot happens to have.

This is a blog about Agile open-source invention of both hardware and software for the benefit of all humanity. I welcome you to join me. Presently this blog is only for my essays; the real work is begin published at our GitHub repos: https://github.com/PIFAH/PIFAH . Follow me on twitter at @RobertLeeRead.

Wednesday, December 5, 2012

Tuesday, October 16, 2012

No-Update update, and call for volunteers

I took the weekend off and then got sick.

However, my hope is this coming weekend we can really test the newly polished panels. I have some hope that we can actually cook a 1/3rd of a hot dog, which will be a major breakthrough---and a long time coming, if you have been following this little project.

However, let me use this "dead air" to once again call for volunteers, or participants in this project. It's really great working with Elliot, who is a fine mathematician and engineer. However, I would love to get someone else involved in the project.

What needs to be done? Well, in the first place we need people to join the conversation about what we are trying to do. Is the idea of an demonstration project really worthwhile at all? We need your help in working this through.

However, here are some other practical things that need to be done:

One of my personal heroes is Buckminster Fuller. I've ready everything he ever wrote, I think, and thought deeply about his life. I would like to accomplish a fraction as much as he did. But he made some mistakes. He did now work hard enough to get his ideas accepted. I am consciously not trying to create a new technology---I am trying to make an old technology acceptable. In this, I need your help. So, if you have any interest, or even just a comment, please comment or send me email (read.robert at gmail dot com).

However, my hope is this coming weekend we can really test the newly polished panels. I have some hope that we can actually cook a 1/3rd of a hot dog, which will be a major breakthrough---and a long time coming, if you have been following this little project.

However, let me use this "dead air" to once again call for volunteers, or participants in this project. It's really great working with Elliot, who is a fine mathematician and engineer. However, I would love to get someone else involved in the project.

What needs to be done? Well, in the first place we need people to join the conversation about what we are trying to do. Is the idea of an demonstration project really worthwhile at all? We need your help in working this through.

However, here are some other practical things that need to be done:

- We need someone to design the cooking chamber in such a way that it actually is convenient to cook with.

- We need someone to design the waist-high frame so that, just like a gas-powered grill, you can work at a convenient height and have little shelves to rest your food on as you prepare it on the grill.

- We need someone to design the counter-balance that will let us use a Dobsonian telescope mount and keep the collector aimed at the son.

- We need someone to start designing an electronic sensing and timing module. For example, although it is not used by most people at the park, we would really like to be able to measure:

- The wattage produced by the collector,

- The internal temperature of food,

- The temperature history of a closed container (distinct from grilling, I know.)

One of my personal heroes is Buckminster Fuller. I've ready everything he ever wrote, I think, and thought deeply about his life. I would like to accomplish a fraction as much as he did. But he made some mistakes. He did now work hard enough to get his ideas accepted. I am consciously not trying to create a new technology---I am trying to make an old technology acceptable. In this, I need your help. So, if you have any interest, or even just a comment, please comment or send me email (read.robert at gmail dot com).

Saturday, October 6, 2012

Polishing Can be a Dirty Job

Dear Fellow Inventors,

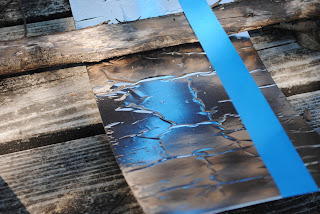

Two weekends ago Elliot and I measured unpolished aluminum panels in our cooker and found that they were far less effective than aluminum foil panels. We decided that we had to construct fully polished and correctly cut panels, both to measure them absolutely and to compare them to foil.

We found that polishing is rather difficult work. There are videos on YouTube that show you how to do it, but a fundamental secret is that you need to the most powerful polishing tool you can get. We bought one for about $200, a huge, heavy, dangerously powerful Hitachi tool pictured below. Using this, I was able to polish all 4 panels in about 6 hours. It is, however, a dirty, boring and time-consuming job.

The final result is a mirror-like, but not quite mirror-quality, reflective surface. We hope to test the new oven with these panels soon, and I am optimistic we will have better performance than ever before.

Two weekends ago Elliot and I measured unpolished aluminum panels in our cooker and found that they were far less effective than aluminum foil panels. We decided that we had to construct fully polished and correctly cut panels, both to measure them absolutely and to compare them to foil.

We found that polishing is rather difficult work. There are videos on YouTube that show you how to do it, but a fundamental secret is that you need to the most powerful polishing tool you can get. We bought one for about $200, a huge, heavy, dangerously powerful Hitachi tool pictured below. Using this, I was able to polish all 4 panels in about 6 hours. It is, however, a dirty, boring and time-consuming job.

The final result is a mirror-like, but not quite mirror-quality, reflective surface. We hope to test the new oven with these panels soon, and I am optimistic we will have better performance than ever before.

Sunday, September 23, 2012

Unpolished=bad. And we can toast bread.

Today Elliot and I tested the oven with the unpolished aluminum panels that we installed with the tensioning system last time. They are ineffective.

Here are are timings and temperature measurements (Fahrenheit):

0:00 -- 79

1:00 -- 80

2:00 -- 80

3:00 -- 81

4:00 -- 81

6:00 -- 81

This is very disappointing, but accords with the subjective "hand test"---I could hold the palm of my hand at the target area for 25 seconds, which is longer than the others. We then installed our mis-cut polished panels that have a near-mirror like surface. The "hand test" lasted to a count of 13. Here is the time measurement:

0:00 -- 92

1:00 -- 93

2:00 -- 94

3:00 -- 97

4:00 -- 98

5:00 -- 99

6:00 -- 100

7:00 -- 100

8:00 -- 100

Note that we adopted an experimental procedure of "stirring" the 2 cups of water with the thermometer, which made our temperatures much more stable.

We went inside for approximately 30 minutes to plot our next course of action, and when we returned the water was at 130F (we took it out and measured it very reliably.) At this point, the oven was not aimed particularly well due to the apparent motion of the sun. This was basically the same performance we got previously with the same miscut polished panels.

Our conclusion is: we really need to create properly polished, properly cut panels and test them. That will be my mission for this week.

We performed two other interesting experiments. We took 3 panels of posterboard that had foil glued to them via 3 distinct mechanisms: contact cement, rubber cement, and heated rubber cement. We curled them (with tape) and left them in the sun. All three developed some wrinkles. The heated rubber cement seems to have the fewest wrinkles. We bought some much stiffer poster board and Elliot is going to manufacture some new panels for us to test with additionally, in hopes of doing a side-by-side test of foil-on-board vs. polished aluminum.

Finally, we stuck a piece of bread in the target area, aimed it, and left it alone. We went back about 45 minutes later (we weren't really tracking time closely.) The oven had toasted the bread to browning, at least in some of the region. (Note that our target area is a 3" x 3" square, significantly smaller than a slice of bread.

It isn't visible but the whole 3" square was dry and staled (that is dehydrated---what we think of as toasted.) Obviously, the burned part received more intense solar radiation. Here is the back of the same slice, with the browning showing through.

This is, in fact, the first thing that we have eaten which we "cooked".

Here are are timings and temperature measurements (Fahrenheit):

0:00 -- 79

1:00 -- 80

2:00 -- 80

3:00 -- 81

4:00 -- 81

6:00 -- 81

|

| Close-up of polished panels installed on top of unpolished panels. |

0:00 -- 92

1:00 -- 93

2:00 -- 94

3:00 -- 97

4:00 -- 98

5:00 -- 99

6:00 -- 100

7:00 -- 100

8:00 -- 100

Note that we adopted an experimental procedure of "stirring" the 2 cups of water with the thermometer, which made our temperatures much more stable.

We went inside for approximately 30 minutes to plot our next course of action, and when we returned the water was at 130F (we took it out and measured it very reliably.) At this point, the oven was not aimed particularly well due to the apparent motion of the sun. This was basically the same performance we got previously with the same miscut polished panels.

Our conclusion is: we really need to create properly polished, properly cut panels and test them. That will be my mission for this week.

We performed two other interesting experiments. We took 3 panels of posterboard that had foil glued to them via 3 distinct mechanisms: contact cement, rubber cement, and heated rubber cement. We curled them (with tape) and left them in the sun. All three developed some wrinkles. The heated rubber cement seems to have the fewest wrinkles. We bought some much stiffer poster board and Elliot is going to manufacture some new panels for us to test with additionally, in hopes of doing a side-by-side test of foil-on-board vs. polished aluminum.

|

| Close-up of one of the panels |

|

| Cold rubber cement--large wrinkles. |

| |

| Our three foil-covered posterboard panels, heating in the sun---showing developing wrinkles in all cases. |

Finally, we stuck a piece of bread in the target area, aimed it, and left it alone. We went back about 45 minutes later (we weren't really tracking time closely.) The oven had toasted the bread to browning, at least in some of the region. (Note that our target area is a 3" x 3" square, significantly smaller than a slice of bread.

|

| Our toasted bread. |

This is, in fact, the first thing that we have eaten which we "cooked".

Friday, September 21, 2012

What we are trying to do with the Solar Oven

An advocate for the devil should challenge us with these questions:

Along the same lines, one can construct an oven out of mirrors, unpolished aluminum, polished aluminum, and aluminum foil (we have tried all of these!) but I have not found a resource that actually compares these reflectors from a practical point of view. I hope at least we can contribute to this kind of practical knowledge. I did not go to graduate school for seven years to do such practical engineering, which almost descends to "craft" rather than engineering---but I am not ashamed to contribute it.

We are intentionally attempting to apply Agile Software Methodology to this development. That is why we are presently collecting one sqare foot (or 100 watts) or solar energy rather than one square meter (or 600 watts, approximately the power of microwave oven.) If we cannot build an effective oven that conveniently allows one to cook a very small portion of food, we have no business investing in a larger oven that would be have more potential.

We are currently building a long, narrow CPC because we believe that to build a cooker more convenient for the grill master or chef than those previously developed, we need to achieve higher temperatures. Existing solar cookery tends to fail because it forces a culturally unappealing change in cooking style. Although I personally am fruitarian(ish) and don't often eat barbecue or hot dogs, that is what Americans cook as a social food at the park. These foods can be made edible with long, slow cooking typical of solar cookers---but not palatable. The culturally preference is for slighty-charred food what is hot to warm at the center. To make this experience as similar to what it is with charcoal, we need to produce the same food, and we must produce it in about the same amount of time. This implies that we must inject heat into the food about as fast as being a few inches above a charcoal fire. Therefore the high concentrations offered by non-imaging optics seems like a reasonable approach.

It is possible that a broader CPC, involute, or other design would be better. However, "long" CPC seems to be a good compromise in that it allows input into an insulated chamber with a relatively small port, which presumably will allow a higher overall temperature, and the ability to perform "grilling" style cooking in which the heat is primarily radiated rather than conducted into the food.

There are several worthy goals that we can accomplish, though none of them would be considered a theoretic advance of optics:

- Why are you researching such fully understood technology?

- Why are you building something so small that it can't even cook a hot dog?

- Why are you using such a long, narrow collector?

- What can you hope to contribute to technology of solar cooking?

Along the same lines, one can construct an oven out of mirrors, unpolished aluminum, polished aluminum, and aluminum foil (we have tried all of these!) but I have not found a resource that actually compares these reflectors from a practical point of view. I hope at least we can contribute to this kind of practical knowledge. I did not go to graduate school for seven years to do such practical engineering, which almost descends to "craft" rather than engineering---but I am not ashamed to contribute it.

We are intentionally attempting to apply Agile Software Methodology to this development. That is why we are presently collecting one sqare foot (or 100 watts) or solar energy rather than one square meter (or 600 watts, approximately the power of microwave oven.) If we cannot build an effective oven that conveniently allows one to cook a very small portion of food, we have no business investing in a larger oven that would be have more potential.

We are currently building a long, narrow CPC because we believe that to build a cooker more convenient for the grill master or chef than those previously developed, we need to achieve higher temperatures. Existing solar cookery tends to fail because it forces a culturally unappealing change in cooking style. Although I personally am fruitarian(ish) and don't often eat barbecue or hot dogs, that is what Americans cook as a social food at the park. These foods can be made edible with long, slow cooking typical of solar cookers---but not palatable. The culturally preference is for slighty-charred food what is hot to warm at the center. To make this experience as similar to what it is with charcoal, we need to produce the same food, and we must produce it in about the same amount of time. This implies that we must inject heat into the food about as fast as being a few inches above a charcoal fire. Therefore the high concentrations offered by non-imaging optics seems like a reasonable approach.

It is possible that a broader CPC, involute, or other design would be better. However, "long" CPC seems to be a good compromise in that it allows input into an insulated chamber with a relatively small port, which presumably will allow a higher overall temperature, and the ability to perform "grilling" style cooking in which the heat is primarily radiated rather than conducted into the food.

There are several worthy goals that we can accomplish, though none of them would be considered a theoretic advance of optics:

- We can document our experience trying to make good reflectors.

- We can develop approaches to build complex curves out of widely available tools and materials.

- We can attempt to measure an actual instance of a CPC and compare it to the easily calculated theoretical potential.

- We can develop aiming and positioning technology that is broadly applicable.

But personally, I just think it would be a powerful artifact to build even a single device, at whatever expense, that is as convenient to use a charcoal grill that requires no fuel at all.

Sunday, September 16, 2012

Rainy Day Construction

Today it rained in Austin. All day. Which is good, since we are in a severe drought. It was not good for measuring the effective of our solar grill, however.

Elliot and I did work a solid seven hours, however, and accomplished two things. Elliot tested three different adhesive systems for gluing foil to posterboard. These were rubber cement, heated rubber cement, and contact cement. All of them look good when first constructed, but our initial experience is that rubber cement eventually wrinkles when you bend it to shape and put it in the sun. I believe that contact cement will keep this from happening, but of course as scientists we don't accept any hypothesis fully until tested---and even then it remains provisional.

The other major work was the completion of our "pressure conformity system." Previously we had glued the flat panels to the parabolic ribs, creating the shape of a parabola. Unfortunately, this also damaged the ribs, making them essentially unreusable. Our current system shows great promise. We constructed aluminum brackets (with a pair of tin snips) that hold the bottom edge of the panel in two little lips, and then we apply pressure downward to the top of the panel with a mirror-holder wired to a turnbuckle. The pressure pushes it solidly against the ribs, apparently producing a nice parabola.

We then performed a "green paper test" of our resulting system using our

unpolished panels. The results are pictured below. I personally think

the drop-off in intensity outside the "cross" pattern is very troubling

for our overall concentration. Next weekend we are hoping to

experiment with this more completely.

Our biggest questions now are:

Elliot and I did work a solid seven hours, however, and accomplished two things. Elliot tested three different adhesive systems for gluing foil to posterboard. These were rubber cement, heated rubber cement, and contact cement. All of them look good when first constructed, but our initial experience is that rubber cement eventually wrinkles when you bend it to shape and put it in the sun. I believe that contact cement will keep this from happening, but of course as scientists we don't accept any hypothesis fully until tested---and even then it remains provisional.

The other major work was the completion of our "pressure conformity system." Previously we had glued the flat panels to the parabolic ribs, creating the shape of a parabola. Unfortunately, this also damaged the ribs, making them essentially unreusable. Our current system shows great promise. We constructed aluminum brackets (with a pair of tin snips) that hold the bottom edge of the panel in two little lips, and then we apply pressure downward to the top of the panel with a mirror-holder wired to a turnbuckle. The pressure pushes it solidly against the ribs, apparently producing a nice parabola.

|

| Clip-and-turnbuckle system (wide angle.) |

|

| Mirror clip with wire going over bolt to put force downard and into rib. |

|

| Twisted wire through base as a turnbuckle attachment point. |

|

| Top of mirror clip pressing down on panel. |

|

| Green-paper test with ceiling light. Note strong "cross" pattern and mirror clips on panels. |

|

| Another view of the "green paper" test. Note troubling silver voids in the corners. |

|

| Green paper test from less than acceptance angle. We believe we should be seeing green everywhere! |

- How efficient is our concentrator in absolute quantifiable terms?

- Are very small deviations from a perfect parabola enough to cause major decreases in efficiency?

- How much would panels polished to a mirror-like finish improve our concentration?

Sunday, September 9, 2012

Additional Experiments Performed Today

Elliot and I worked on the solar oven again today, without any particularly dramatic results. Nonetheless I summarize the results here.

Note that Elliot invented a very valuable tool for testing our optics, which we call the "green paper test". If you put a sheet of green paper at the aperture, then when looking directly down into the oven you should see a solid glow of green from the entire machine. This is partially true of our best panels to date, as show below.

Note that foil wrinkles disrupt the solid green pattern and probably cause some inefficiency---but the field of green is still better than that shown below!

As any good scientist should do, we repeated the experiments of that last weekend. That is, using the same apparatus and the same cup of darkened water, we measured the temperature every two minutes. The experiment was performed at 1:00 pm, where where was no danger of the sun not striking a significant face of our darkened water.

Time -- Temperature (Fahrenheit)

0:00 -- 87 F

2:00 -- 143 F

4:00 -- 152 F

6:00 -- 155 F

8:00 -- 159 F

10:00 -- 162 F

12:00 -- 165 F

14:00 -- 170 F

16: 00 -- 172 F

18:00 -- 172 F

This saturation point corresponds to what we measured in the fluid last weekend (after 45 minutes!) once we stuck the tip of the thermometer down in the liquid. So there were no surprises here.

He noted that once removed from the oven, our fluid read a temperature of 143 F in just about 45 seconds. This suggest that our cooking chamber (a Mason jar) does not have very good insulation.

We then sought to reconfirm our wattage by changing to 2 cups of liquid. We carefully covered the oven so that we could uncover it precisely when we began timing, so that we could measure the wattage when the water was cool (before it began losing heat rapidly to ambient environment, as it apparently does at 175 F.) We also switched to once-per-minute measurement.

Here are the results of what I will call the "most careful" experiment:

0:00 -- 90 F

1:00 -- 112 F

2:00 -- 122 F

3:00 -- 128 F

4:00 -- 132 F

5:00 -- 134 F

6:00 -- 138 F

7:00 -- 139 F

8:00 -- 139 F

We are not entirely sure what it means that saturation temperature of a higher amount of water was so much lower, apparently.

We then sought to test if our polished aluminum panels would be better than the aluminum foil. I had polished these panels previously. Unfortunately, they were miscalculated and are cut too narrow, as can be seen in the photographs below. As I've tried to convey in the photographs below, these panels are "mirror-like" but not mirrors. I polished them with a drill that was really too small for the job; compared to a really professional polish they are half-done---yet they reflect an image easily enough for most of their area.

Unfortunately, these panels leaked a lot of light out the sides that should have been reflected to the target, as shown by the "green paper test" and the other photos.

The disappointing results of this leaky machine are given below:

0:00 -- 81 F

1:00 -- 83 F

2:20 -- 89 F (note time is 20 seconds out of order, we forgot to measure it!)

3:00 -- 90 F

4:00 -- 93 F

5:00 -- 97 F

6:00 -- 98 F

7:00 -- 99 F

8:00 -- 99 F

This was a very disappointing result, so we attempted to amend the machine by taping aluminum foil over the seams. Below you can see the mediocre green paper test of our result, showing the crinkly foil there in.

The results of this measurement were very disappointing---which we interpret to mean that the incorrect geometry trumps the somewhat more specular aluminum. This was again with 2 cups of water.

0:00 -- 80 F

1:00 -- 82 F

2:00 -- 82 F

3:00 -- 97 F

4:00 - 99 F

5:00 -- 100 F

6:00 -- 102 F

7:00 -- 99 F (moved tip of the thermometer here, probably lower

8:00 -- 106 F

9:00 -- 110 F

10:00 -- 112 F

11:00 -- 112 F

12:00 -- 117 F

13:00 -- 114 F

After agitating (stirring) the water, it read 117 F. This suggest that our water is not (at least at low temperatures) all the same temperature in all places. We resolved to agitate the water a bit during future experiments.

We spend the rest of the time building a bracket to hold our new, correctly shaped but unpolished panels in position. In the past we have used hot-melt glue and duct-tape. By pressing downward (quite about, perhaps 6-10 pounds of pressure), the panel can be made to conform well to our parabolic ribs without requiring glue or tape. We hope this system allows us to change panels more effectively in the future.

Our general goal for next weekend is to test our unpolished but properly cut panels, and then to either polish them or cover them with foil and test them again.

One may ask what our goal here is. Basically, we want to build a legitimately well-constructed CPC collector as a baseline. We want to show that we are correctly calculating the wattage of the machine and measuring its efficiency.

Moreover, we want to be able to cook a small amount of meat (that being the typical outdoor usage) with this oven before we contemplate scaling it up to provide higher-wattage overall. We understand of course that with only 100 watts of input (since that is what the sun provides on 1-square foot) we cannot hope to cook something large quickly. However, we want to demonstrate enough concentrated power that it is conveniently short to cook a small amount of meat (say half a hot-dog) before we consider constructing a larger version that might approach what you can get out of typical charcoal barbecue grill.

Tomorrow I will recompute the wattage of our 2-cup experiment to compute our overall efficiency.

* * * (Post scripted)

The formula for converting a change in temperature of dt of a mass m of water in s seconds to power is:

P = (dt * m * 4.18) / s,

where P is in Watts, s is in seconds, m is in grams, and dt in the change in temperature in Celsius Kelvin. The 4.18 is the number of Joules in a calorie.

Unfortunately, this suggest that I am either in error or misread the thermometer on the first measurement or that the thermometer did not read the entire mass of the water.

According to the "most careful" experiment, we raised 2 cups (256 grams) of water 22 degrees Fahrenheit, or 12.2 degrees Celsius in only 60 seconds, which comes out to: 217 Watts. Since we believe the solar input on square foot only 100 Watts, I am at a loss to explain this.

I suspect that our thermometer was not giving a true reading of the entire thermal mass of all the water.

Note that Elliot invented a very valuable tool for testing our optics, which we call the "green paper test". If you put a sheet of green paper at the aperture, then when looking directly down into the oven you should see a solid glow of green from the entire machine. This is partially true of our best panels to date, as show below.

|

| Green-paper test for our foil-covered poster-board |

As any good scientist should do, we repeated the experiments of that last weekend. That is, using the same apparatus and the same cup of darkened water, we measured the temperature every two minutes. The experiment was performed at 1:00 pm, where where was no danger of the sun not striking a significant face of our darkened water.

Time -- Temperature (Fahrenheit)

0:00 -- 87 F

2:00 -- 143 F

4:00 -- 152 F

6:00 -- 155 F

8:00 -- 159 F

10:00 -- 162 F

12:00 -- 165 F

14:00 -- 170 F

16: 00 -- 172 F

18:00 -- 172 F

This saturation point corresponds to what we measured in the fluid last weekend (after 45 minutes!) once we stuck the tip of the thermometer down in the liquid. So there were no surprises here.

He noted that once removed from the oven, our fluid read a temperature of 143 F in just about 45 seconds. This suggest that our cooking chamber (a Mason jar) does not have very good insulation.

We then sought to reconfirm our wattage by changing to 2 cups of liquid. We carefully covered the oven so that we could uncover it precisely when we began timing, so that we could measure the wattage when the water was cool (before it began losing heat rapidly to ambient environment, as it apparently does at 175 F.) We also switched to once-per-minute measurement.

Here are the results of what I will call the "most careful" experiment:

0:00 -- 90 F

1:00 -- 112 F

2:00 -- 122 F

3:00 -- 128 F

4:00 -- 132 F

5:00 -- 134 F

6:00 -- 138 F

7:00 -- 139 F

8:00 -- 139 F

We are not entirely sure what it means that saturation temperature of a higher amount of water was so much lower, apparently.

We then sought to test if our polished aluminum panels would be better than the aluminum foil. I had polished these panels previously. Unfortunately, they were miscalculated and are cut too narrow, as can be seen in the photographs below. As I've tried to convey in the photographs below, these panels are "mirror-like" but not mirrors. I polished them with a drill that was really too small for the job; compared to a really professional polish they are half-done---yet they reflect an image easily enough for most of their area.

| ||||

| Polished, but imperfect aluminum panel. |

|

| |

| Green paper test of polished, but too-narrow panels. |

|

| Leaky machine in the sun, with bright ellipses of light shining through panel seams instead of to target. |

| ||

| Close up of a leaky seam. |

0:00 -- 81 F

1:00 -- 83 F

2:20 -- 89 F (note time is 20 seconds out of order, we forgot to measure it!)

3:00 -- 90 F

4:00 -- 93 F

5:00 -- 97 F

6:00 -- 98 F

7:00 -- 99 F

8:00 -- 99 F

This was a very disappointing result, so we attempted to amend the machine by taping aluminum foil over the seams. Below you can see the mediocre green paper test of our result, showing the crinkly foil there in.

| ||||||||||||

| View taken with flash of our mis-cut panels with foil in place (note foil appears to be ineffective here!) |

|

| Outside version of the green-paper test. |

0:00 -- 80 F

1:00 -- 82 F

2:00 -- 82 F

3:00 -- 97 F

4:00 - 99 F

5:00 -- 100 F

6:00 -- 102 F

7:00 -- 99 F (moved tip of the thermometer here, probably lower

8:00 -- 106 F

9:00 -- 110 F

10:00 -- 112 F

11:00 -- 112 F

12:00 -- 117 F

13:00 -- 114 F

After agitating (stirring) the water, it read 117 F. This suggest that our water is not (at least at low temperatures) all the same temperature in all places. We resolved to agitate the water a bit during future experiments.

We spend the rest of the time building a bracket to hold our new, correctly shaped but unpolished panels in position. In the past we have used hot-melt glue and duct-tape. By pressing downward (quite about, perhaps 6-10 pounds of pressure), the panel can be made to conform well to our parabolic ribs without requiring glue or tape. We hope this system allows us to change panels more effectively in the future.

Our general goal for next weekend is to test our unpolished but properly cut panels, and then to either polish them or cover them with foil and test them again.

One may ask what our goal here is. Basically, we want to build a legitimately well-constructed CPC collector as a baseline. We want to show that we are correctly calculating the wattage of the machine and measuring its efficiency.

Moreover, we want to be able to cook a small amount of meat (that being the typical outdoor usage) with this oven before we contemplate scaling it up to provide higher-wattage overall. We understand of course that with only 100 watts of input (since that is what the sun provides on 1-square foot) we cannot hope to cook something large quickly. However, we want to demonstrate enough concentrated power that it is conveniently short to cook a small amount of meat (say half a hot-dog) before we consider constructing a larger version that might approach what you can get out of typical charcoal barbecue grill.

Tomorrow I will recompute the wattage of our 2-cup experiment to compute our overall efficiency.

* * * (Post scripted)

The formula for converting a change in temperature of dt of a mass m of water in s seconds to power is:

P = (dt * m * 4.18) / s,

where P is in Watts, s is in seconds, m is in grams, and dt in the change in temperature in Celsius Kelvin. The 4.18 is the number of Joules in a calorie.

Unfortunately, this suggest that I am either in error or misread the thermometer on the first measurement or that the thermometer did not read the entire mass of the water.

According to the "most careful" experiment, we raised 2 cups (256 grams) of water 22 degrees Fahrenheit, or 12.2 degrees Celsius in only 60 seconds, which comes out to: 217 Watts. Since we believe the solar input on square foot only 100 Watts, I am at a loss to explain this.

I suspect that our thermometer was not giving a true reading of the entire thermal mass of all the water.

Monday, September 3, 2012

Flawed experiments succeed at 12% efficiency

Today Elliot and I tested our solar oven. As is often the case, we learned a lot, in this case that our original experiments were flawed. Nonetheless we got some good data for establishing a baseline to be ready to improve our collector.

Let me reintroduce our situation. We are currently using our modular solar oven that makes a clear distinction between the concentrator module and the frame module. The frame module is based on a Dobsonian telescope frame. It provides both a holder for the cooking chamber and place to bolt the concentrator such that the cooking chamber is held at the exit pupil of the concentrator. The concentrator is a square (3d) compound parabolic collector, whose exit pupil is 9 square inches and input pupil is 144 square inches, providing a theoretic concentrating power of 16.

At present, our concentrator uses reflective panels made by gluing aluminum to poster board. As such as it is a little flimsy, and visibly imperfect both in having wrinkles and not being perfectly parabolic.

Nonetheless, it concentrates sunlight well enough that is painful to hold the palm of your hand at the exit pupil for more than 15 or 20 seconds.

Today, we attempted to measure the ability and rate of heating a cup of water. We darkened the water with food coloring, and placed it in a 1-quart Mason (canning) jar. We poked a small hole in the lid, allowing us to insert an instant-read thermometer. The jar could then be turned as if to rest on its side and placed in the frame module, forming a cooking chamber, with the thermometer easily readable from the outside. The jar was backed by aluminum foil to reflect radiation back into the jar.

Our initial experimental plan was to aim the oven at the sun and measure the temperature every 5 minutes. Here are our results:

This looks like a success. Little did we realize that in fact our thermometer was NOT immersed in the water! It is much easier to heat the tip of a thermometer than a cup of water. This was a major flaw that invalidated most the of the experiment. We measured the water temperature at 170 degrees F after the termination of the experiment.

So, of course, we attempted to repeat the experiment, making sure that our thermometer was fully immersed. We also decided to take measurements every 2 minutes.

Here are our results:

Nonetheless, there is nothing "invalid" about our second experiment, save that it measures an effect that we believe would be much greater if the sun was higher in the sky, or if our darkened object were a solid that would have stayed in the middle of our exit pupil.

Therefore, based on the data that we did collect, I have computed the wattage of our oven, and therefore its efficiency.

Here is my approach---if you see a flaw, please inform me.

A cup of water weighs 128 grams. The temperatures was raised from 80 F to 137 F in 24 minutes. Converted to Celsius, this is 31.667 degrees of increase. By the definition of calories, this is 128 * 31.667 = 4053.28 calories. Converting to Joules, this is 16983.27 Joules. Twenty-four minutes is 1,440 seconds. Since a Watt is a unit of power expressed as Joules per second, the sun powered our oven at effectively 11.79 watts over this period of time to our water.

Taking as a general rule-of-thumb estimate a solar input of 100 watts per square foot, our oven therefore achieved an efficiency of about 12% during these 24 minutes.

This is modest, but I am very pleased by it. We have achieved this with a concentrator we are pretty sure we can improve upon. We have a established a baseline that will allow us to test this hypothesis.

It is possible that nobody has ever actually attempted to cook with a compound parabolic collector before. It is therefore possible that we are doing something truly unique.

Perhaps more importantly, we have are getting close to be able to actually cook something.

One might look at all of our effort and ridicule how little we have accomplished, given that it is so easy to cook with charcoal, gas, or electricity. However, I remained convinced that any increase in solar energy usage is a step forward for all mankind. The possibility of using this on a personal level here in a America to replace the use of charcoal in outdoor barbecue grills seems like a worthy project, both in terms of reducing fossil fuel usage and carbon footprint and raising consciousness about the possibility of using solar energy more broadly.

Let me reintroduce our situation. We are currently using our modular solar oven that makes a clear distinction between the concentrator module and the frame module. The frame module is based on a Dobsonian telescope frame. It provides both a holder for the cooking chamber and place to bolt the concentrator such that the cooking chamber is held at the exit pupil of the concentrator. The concentrator is a square (3d) compound parabolic collector, whose exit pupil is 9 square inches and input pupil is 144 square inches, providing a theoretic concentrating power of 16.

At present, our concentrator uses reflective panels made by gluing aluminum to poster board. As such as it is a little flimsy, and visibly imperfect both in having wrinkles and not being perfectly parabolic.

|

| Elliot with the Oven |

Nonetheless, it concentrates sunlight well enough that is painful to hold the palm of your hand at the exit pupil for more than 15 or 20 seconds.

Today, we attempted to measure the ability and rate of heating a cup of water. We darkened the water with food coloring, and placed it in a 1-quart Mason (canning) jar. We poked a small hole in the lid, allowing us to insert an instant-read thermometer. The jar could then be turned as if to rest on its side and placed in the frame module, forming a cooking chamber, with the thermometer easily readable from the outside. The jar was backed by aluminum foil to reflect radiation back into the jar.

|

| ||

| Darkened water with thermometer inserted |

Our initial experimental plan was to aim the oven at the sun and measure the temperature every 5 minutes. Here are our results:

- 0 minutes : 80 degrees F

- 5 minutes : 130 degrees F

- 10 minutes : 140 degrees F

- 15 minutes : 153 degrees F

- 20 minutes : 160 degrees F

- 25 minutes : 163 degrees F

- 30 minutes : 165 degrees F

- 35 minutes : 180 degrees F

- 40 minutes : 182 degress F

- 45 minutes : 190 degrees F

This looks like a success. Little did we realize that in fact our thermometer was NOT immersed in the water! It is much easier to heat the tip of a thermometer than a cup of water. This was a major flaw that invalidated most the of the experiment. We measured the water temperature at 170 degrees F after the termination of the experiment.

So, of course, we attempted to repeat the experiment, making sure that our thermometer was fully immersed. We also decided to take measurements every 2 minutes.

|

| The oven in the Texas sun awaiting our tests |

Here are our results:

- 0 minutes : 80 degrees F

- 2 minutes : 93 degrees F

- 4 minutes : 99 degrees F

- 6 minutes : 103 degrees F

- 8 minutes : 108 degrees F

- 10 minutes : 113 degrees F

- 12 minutes : 118 degrees F

- 14 minutes : 120 degrees F

- 16 minutes : 121 degress F

- 18 minutes : 122 degrees F

- 20 minutes : 130 degrees F

- 22 minutes : 132 degrees F

- 24 minutes : 137 degrees F

- 26 minutes : 138 degrees F

- 28 minutes : 140 degrees F

- 30 minutes : 141 degrees F

- 32 minutes : 141 degrees F

Nonetheless, there is nothing "invalid" about our second experiment, save that it measures an effect that we believe would be much greater if the sun was higher in the sky, or if our darkened object were a solid that would have stayed in the middle of our exit pupil.

Therefore, based on the data that we did collect, I have computed the wattage of our oven, and therefore its efficiency.

Here is my approach---if you see a flaw, please inform me.

A cup of water weighs 128 grams. The temperatures was raised from 80 F to 137 F in 24 minutes. Converted to Celsius, this is 31.667 degrees of increase. By the definition of calories, this is 128 * 31.667 = 4053.28 calories. Converting to Joules, this is 16983.27 Joules. Twenty-four minutes is 1,440 seconds. Since a Watt is a unit of power expressed as Joules per second, the sun powered our oven at effectively 11.79 watts over this period of time to our water.

Taking as a general rule-of-thumb estimate a solar input of 100 watts per square foot, our oven therefore achieved an efficiency of about 12% during these 24 minutes.

This is modest, but I am very pleased by it. We have achieved this with a concentrator we are pretty sure we can improve upon. We have a established a baseline that will allow us to test this hypothesis.

It is possible that nobody has ever actually attempted to cook with a compound parabolic collector before. It is therefore possible that we are doing something truly unique.

Perhaps more importantly, we have are getting close to be able to actually cook something.

One might look at all of our effort and ridicule how little we have accomplished, given that it is so easy to cook with charcoal, gas, or electricity. However, I remained convinced that any increase in solar energy usage is a step forward for all mankind. The possibility of using this on a personal level here in a America to replace the use of charcoal in outdoor barbecue grills seems like a worthy project, both in terms of reducing fossil fuel usage and carbon footprint and raising consciousness about the possibility of using solar energy more broadly.

Sunday, August 26, 2012

Update on Solar Oven

Dear Fellow Inventors,

Before I left on vacation for France, Elliot and I were working on polishing aluminum. While I was gone, he covered posterboard with aluminum foil, and achieved our best success to day. With those imperfect panels, the concentrator produces enough concentration to be painful on the palm of the hand after about 15 seconds.

My first reaction to this was to despair that it has taken us so long to get this far; then this changed to joy that we were making progress.

We then attempted to cook a tablespoon of scrambled egg in a glass jar. The jar got hot---painful to the touch, and hot enough that the cap leaked, probably from thermal expansion. Unfortunately the egg did not solidify. This is rather sad.

One of the problems that we had was that it was cumbersome to hold the oven chamber in place. We were using duct tape, and it never really held on correctly. Aiming the concentrator required us to sit their and hold it and was somewhat error prone.

After some consultation, we decided that, although we want to stick to an "Agile" development methodology, the time had come to us invest in a better frame so that we could hold a cooking chamber in place. This would allow us to perform repeatable cooking experiments, which are too cumbersome at present.

Our basic system now consists of two modules: the concentrator, and the oven frame. I personally suspect we will have to think of the interface between the two as a third module. The purpose of the modules is to be able to change one without having to change other.

We believe the concentrator, which should produce 16 suns of concentration, is producing less than 8, and I personally believe we are not utilizing all of that due to the interface. However, the new frame should allow us to test this more easily.

So, after making up this plan, I spend the day (about 7 hours total, including shopping time), constructing the frame shown in the photographs below. This cost about $35 for the plywood and the bridging wood, and a small number of 1.5 inch and 1 inch wood screws and 4 1/4 inch bolts.

The basic design of the frame is based on that of the Dobsonian Telescope frame. I built such a telescope about 10 years ago with my son, although I through the frame away. This is a well known approach to "aiming" an object of approximately this size. The relationship to astronomy is obvious. We might someday complete the azimuth and altitude mount, but for today I just built the semicircular base that our concentrator could be directly mounted to. Hopefully this base, when propped up with a stick since I can't build a counter-balance until we build a cradle for the frame, will allow us to perform methodical cooking experiments.

Before I left on vacation for France, Elliot and I were working on polishing aluminum. While I was gone, he covered posterboard with aluminum foil, and achieved our best success to day. With those imperfect panels, the concentrator produces enough concentration to be painful on the palm of the hand after about 15 seconds.

My first reaction to this was to despair that it has taken us so long to get this far; then this changed to joy that we were making progress.

We then attempted to cook a tablespoon of scrambled egg in a glass jar. The jar got hot---painful to the touch, and hot enough that the cap leaked, probably from thermal expansion. Unfortunately the egg did not solidify. This is rather sad.

One of the problems that we had was that it was cumbersome to hold the oven chamber in place. We were using duct tape, and it never really held on correctly. Aiming the concentrator required us to sit their and hold it and was somewhat error prone.

After some consultation, we decided that, although we want to stick to an "Agile" development methodology, the time had come to us invest in a better frame so that we could hold a cooking chamber in place. This would allow us to perform repeatable cooking experiments, which are too cumbersome at present.

Our basic system now consists of two modules: the concentrator, and the oven frame. I personally suspect we will have to think of the interface between the two as a third module. The purpose of the modules is to be able to change one without having to change other.

We believe the concentrator, which should produce 16 suns of concentration, is producing less than 8, and I personally believe we are not utilizing all of that due to the interface. However, the new frame should allow us to test this more easily.

So, after making up this plan, I spend the day (about 7 hours total, including shopping time), constructing the frame shown in the photographs below. This cost about $35 for the plywood and the bridging wood, and a small number of 1.5 inch and 1 inch wood screws and 4 1/4 inch bolts.

The basic design of the frame is based on that of the Dobsonian Telescope frame. I built such a telescope about 10 years ago with my son, although I through the frame away. This is a well known approach to "aiming" an object of approximately this size. The relationship to astronomy is obvious. We might someday complete the azimuth and altitude mount, but for today I just built the semicircular base that our concentrator could be directly mounted to. Hopefully this base, when propped up with a stick since I can't build a counter-balance until we build a cradle for the frame, will allow us to perform methodical cooking experiments.

|

| Here is the concentrator mounted on the frame. |

|

| Looking down into the concentrator with aluminum and poster-board panels. |

|

| The cocnentrator bolted to the frame |

|

| These are cut out to allow us to insert a cooking chamber into the target area of the concentrator. |

|

| View From Beneath |

|

| View from Beneath looking through concentrator, showing bridging. |

|

| Mason jar as cooking chamber (would need to be raised an inch or two to be in target area.) |

|

| Mason jar at target area---hopefully this is the view the sun will see! |

Sunday, August 19, 2012

The Feel of France

Dear fellow inventors,

I have not posted in sometime because I have been on vacation in France, visiting Paris, Burgundy, and Nimes.

Elliot and I are continuing to work on the solar oven. I purchased a very powerful polisher, which should allow us to achieve a highly reflective surface to complete our current solar over design in the next few weekends.

In the meantime, for those of you who may care, here is a little essay, a "trip report" if you will, about France.

====

The Feel of France

France is full French persons. More

than the gently rolling hills, the palaces once used by kings and now

used by tourists, the towns grown organically around old walled

cities, the remaining forests, the sheepfolds and white Charolais

cattle glowing in the sun, the 150-year-old stone barns, it is the

French who make France beautiful.

The French are beautiful because they

pay attention. They eat with enthusiasm and savor, and so they do not

eat too much. They have elected a 35-hour work week, and so they have

more time to pay attention to their lives. The women select their

clothes, even simple t-shirts, carefully. Fathers pay attention to

their kids in public. Sales people pay attention to their clients.

They all pay attention to tourists.

The food is not cooked better than the

food in my city of Austin, Texas. I don't believe the French chefs

are on the whole smarter or harder-working than ours are. However,

eating is better in France. In the first place it seems clear that

food production is less factory-oriented than in America, based on

the herds and flocks you see in the fields as you drive along,

evidently eating the summer grass, and the great bales of hay drying

for winter. The signs directing to you “country tomatoes” at low

prices seem to be in direct competition with the markets that sell

the same, evidently local, produce. That these markets are a far more

important part of most peoples lives is of course aided by the fact

that their towns are based on walking and not driving, and of course

it is more efficient to have a market stand when thousands of people

walk by each morning and nobody has to worry about parking.

Perhaps more importantly, the French

pay attention to meals. The meals are better, even if the individual

food items are the same. The French give you just the right amount of

food. The menu design of several small courses encourages a leisurely

enjoyment of a variety of foods. You don't just “have a steak”,

you have an apéritif,

an entrée

, a steak, a glass of wine, and a

desert. In short, you have an experience. The steak is half the size

of what we Texans consider a serving, but it taste twice as good and

weighs have as much in the belly. It is “just right” more often

in France.

Someone decided to plant that line of

sycamores along that roadside 80 years ago, or decided to place the

road along them already, and they were paying attention when they did

so. Someone decided to plant geraniums next to that rose. If France

seems a little less manicured than England, it seems a little less

overwrought and a little more just right.

Americans sometimes think of the French

as rude and lazy, which seem patently absurd. Of course, I prepared

for my visit by not being rude and lazy myself—I learned enough

French to say that I don't speak French well, I learned how to great

people, understand numbers, and say please and thank you. I always

asked if people spoke English before throwing it at them. Usually

their English was better than my French, but we always met on equal

terms, both struggling to communicate in a foreign language. Of the

hundred or so people I interacted with, everyone single one of them

was as helpful as they could be, with the exception of the two

gentlemen who attempted to pickpocket my iPhone on the Metro, and

they had the courtesy not to strike or stab me.

The idea that French are lazy must come

from the 35-hour work week. I think is is better to say the French

have elected not to work at making money as much as Americans have

elected to do so. This is a cultural choice. The French seem to

believe what we say: “Their is more to life than making money.”

It is impossible to be lazy and ride

bikes as much as the French do. I am not widely traveled, I'm sure

there are places where bikes are used even more, but France is a very

bike-friendly place. Even in Paris, there are people riding to work,

and they seem to be treated with kindness and respect by the

automobilists. In America we treat biking as an activity distinct

from transportation, whereas the French seem to a see a continuum of

cycling, from cars diverting carefully around an old gentleman barely

rolling along to the Tour de France. A woman riding her bike to work

in a long skirt is not as colorful or flashy as a rider in a bright

racing jersey zipping by, but caresses the eye rather than striking

it.

The Eiffel Tower is beautiful because

of the attention paid to detail in its design. Its beauty derives

from its just-right proportions, its just-right level of complexity,

its harmonic balance of the bold and the delicate. Fontainebleau is

beautiful because of its harmony, where as the Louvre is

excessive—but then, just as we did, they got rid of the source of

excess, didn't they?

America got lucky after World War II.

The action has been in America since that time, though the USA seems

to be less dominant now. I believe we and the French have a great

deal in common intellectually. Certainly, we have embraced the French

invention of parkour as enthusiastically as the French have embraced

Hollywood and rock n' roll. In science, art, literature, and above

all philosophy, we and French are really kindred spirits. We should

try to give the French some of our brash, loud energy and take from

them some of their balance and harmony.

I left France inspired to live a little

more harmoniously, to try to make things a little more beautifully,

to concentrate a little more on fewer things, and to return.

Monday, July 30, 2012

Update on Polishing Aluminum

Dear Fellow Inventors,

Lately my friend Elliot and I are have been working on a solar oven based on a compound parabolic collector. This has been taking longer than we expected, but has been a great learning experience.

In particular, we have found getting highly specular aluminum to be a problem. (We actually also tried cutting a glass mirror, thought that was even worse!) At present we have been polishing sheet aluminum to a mirror like shine.

This worked, we think, but took a long time. Following a video on youtube called "Dirty Jobs How to Polish Aluminum" http://www.youtube.com/watch?v=gyOodLNI4BQ I went out and bought an 15 amp grinder and the necessary buffing wheels. This was a success in that it greatly increased our polishing speed (though not quite to match the gentleman in the video, how has even more powerful equipment.)

We also attempt to polish aluminum flashing, which is cheaper than the sheet metal we had been using. It polishes the same way, but the additional power (or perhaps heat) from our more powerful grinder tended to crinkle the surface a bit. We found that by using a sheet aluminum backing this problem could be mitigated somewhat.

So at present we are mostly investing time in learning how to manufacture what we want, rather than the actual mathematics and design we want. However, we both feel this is a necessary part of the process.

Wish us well--in a few more weekends we should have good reflectors to tie into our designs.

Lately my friend Elliot and I are have been working on a solar oven based on a compound parabolic collector. This has been taking longer than we expected, but has been a great learning experience.

In particular, we have found getting highly specular aluminum to be a problem. (We actually also tried cutting a glass mirror, thought that was even worse!) At present we have been polishing sheet aluminum to a mirror like shine.

This worked, we think, but took a long time. Following a video on youtube called "Dirty Jobs How to Polish Aluminum" http://www.youtube.com/watch?v=gyOodLNI4BQ I went out and bought an 15 amp grinder and the necessary buffing wheels. This was a success in that it greatly increased our polishing speed (though not quite to match the gentleman in the video, how has even more powerful equipment.)

We also attempt to polish aluminum flashing, which is cheaper than the sheet metal we had been using. It polishes the same way, but the additional power (or perhaps heat) from our more powerful grinder tended to crinkle the surface a bit. We found that by using a sheet aluminum backing this problem could be mitigated somewhat.

So at present we are mostly investing time in learning how to manufacture what we want, rather than the actual mathematics and design we want. However, we both feel this is a necessary part of the process.

Wish us well--in a few more weekends we should have good reflectors to tie into our designs.

Thursday, June 7, 2012

Update on solar oven....

We discovered that we had done a little of the math incorrectly. Elliot has now re-cut the ribs using the CNC laser cutter. (Yay for easy technology!)

I originally asserted that bare aluminum was specular enough for building a concentrating collector. I now think that is only partially true. Investigation with a laser pointer suggests that the "brush marks" on the surface as it came to us allow an estimated 50% of the energy to be perfectly reflected.

I have therefore been polishing our panels. This produces a mirror-like surface, but with "swirls". I've worked about an hour on each of three panels (about 2 square feet to a panel) and not started the fourth. I think with additional labor, or better equipment, such as a car buffer, a truly mirror-like surface can be achieved. (I'm just using a drill right now.)

Hopefully this weekend Elliot and I will get to do a true test.

I originally asserted that bare aluminum was specular enough for building a concentrating collector. I now think that is only partially true. Investigation with a laser pointer suggests that the "brush marks" on the surface as it came to us allow an estimated 50% of the energy to be perfectly reflected.

I have therefore been polishing our panels. This produces a mirror-like surface, but with "swirls". I've worked about an hour on each of three panels (about 2 square feet to a panel) and not started the fourth. I think with additional labor, or better equipment, such as a car buffer, a truly mirror-like surface can be achieved. (I'm just using a drill right now.)

Hopefully this weekend Elliot and I will get to do a true test.

Sunday, May 27, 2012

Today testing a Compound Parabolic Concentrator of Solar Energy

Dear Fellow Public Inventors,

I apologize for not posting more. Although this blog has been silent, I have in fact been making excellent progress. As you may recall I have joined ATX Hackerspace here in Austin. In addition to a space and some valuable tools, such as a CNC laser, cutters, they have a wonderful community of brilliant hackers.

As I mentioned previously, I have mothballed the Merfluke, and have begun working on a Solar Cooker, a preliminary design of which was posted in the blog.

I'm very happy to have formed a friendly partnership with Elliot Hallmark, who is interested in solar power and very knowledgeable about the mathematics of them. Also, he knows how to use the laser cutter, a really fabulous Tom-Swift type tool capable of cutting 1/4" inch hardwood plywood. Below you can find some snapshots of our current design, which Elliot cut from plywood with the laser cutter.

This shape is the famous "Compound Parabolic Concentrator" pioneered by Roland Winston. The entrance pupil is 1 foot square (144 square inches), and the exit pupil is 3" square (9 square inches). If we have perfect reflectance, this should provide a flux concentration of 16 suns! That is, it should be as if 16 suns were shining on the exit pupil. This should in theory be enough to cook something.

I have cut the reflectors out of sheet aluminum. It is unclear to us if this will be an adequate reflector or not.

Elliot and I seem to be harmoniously agreeing to use "Agile" development processes. I personally give my hero Kent Beck credit for a lot of this, but Wikispeed and others are apparently using the same ideas.

Kent's motto is "Do the simplest thing that can possibly work." Elliot and I are trying to do that. We are know of course that 1 square foot of sunlight won't let you cook more than a hard-boiled egg, but we are starting with a miniature model before we build the full-on West Texas hog roast model!

We so far have identified 3 modules that we can change independently: the reflector panels, the CPC (pictured here in plywood with paper panels) and the oven box, which mates to the CPC via a 3"x3" square aperture. Kent's approach to going fast is to "take baby steps as fast as you can". These three modules allow us to independently improve our reflectance, our collector, and our oven.

Our oven is a cardboard box with a meat thermometer jammed into it. Today is a mostly sunny day in Austin. Our hope is to glue the other 3 aluminum panels in place (we're using hot melt glue for now) and see if 1) we can get anywhere close to 16 suns of brightness (I'd settle for 8!) and 2) can we reach a stagnation temperature of 200 or 300 degrees F in the cardboard box.

Note that a big part of what I proposed was vandal-proofing and convenience, and we aren't addressing those things yet, because until we can cook an egg there is no point in it.

Finally, let me say: you are all invited to help! Elliot and I make a great team, I think---I'm providing the funding, and the metal-working skill, and Elliot has done the math and cut the wood, but there is plenty of room for others to contribute. In particular, we will, if successful, eventually need an artist to help us make it attractive, a microprocessor guy to build the temperature monitoring, mechanical engineers to make a smoothly and safely operating oven that food an be taken in and out of, and test chefs! So don't be shy---send me email and work together with us!

Monday, May 14, 2012

Termination of Merfluke Project

On Saturday, I spoke to a group of about 25 people at the Austin Mini-Maker Faire about the Merluke. I think it was very well received.

I am ending the Merfluke project for now, although anyone is welcome to take up where I left off. It is not without some regrets and doubts that I end this project. I don't like to quit.

But one must say "No" to somethings to be able to say "Yes!" to others.

I have begun, along with three friends from Hackerspace ATX, to work on the Public Solar Oven project that I mentioned in this blog. We have already made some progress, which I will report on soon. The great advantage of this project is that precisely that others are assisting me. It is a lot more fun to collaborate than to work in isolation, and nobody ever was interested in assisting with the Merfluke.

I am ending the Merfluke project for now, although anyone is welcome to take up where I left off. It is not without some regrets and doubts that I end this project. I don't like to quit.

But one must say "No" to somethings to be able to say "Yes!" to others.

I have begun, along with three friends from Hackerspace ATX, to work on the Public Solar Oven project that I mentioned in this blog. We have already made some progress, which I will report on soon. The great advantage of this project is that precisely that others are assisting me. It is a lot more fun to collaborate than to work in isolation, and nobody ever was interested in assisting with the Merfluke.

Sunday, April 8, 2012

Merfluke Project Report #5: Yet another failure

Today I Merfluked 700 meters in 25 minutes at Lake Pflugerville.

This is a miserable failure; I can probably swim that distance in 15 minutes or less without any fins at at all.

On the bright side, I have invented an effective abdominal exercise machine. :->.

To explain the history of this trial, you may note that my last experiment taught me that despite my attempt to design pedals that would allow me to keep a firm contact with the Merfluke pedals, it didn't work. To correct this, I bought a pair of swim-fins, sawed the fins off the foot pockets with a hacksaw, and used a hot-melt glue gun to glue the foot pockets onto the pedals.

The glue did not work very well. Within 10 minutes I had broken both foot pockets off. However, since my foot was strapped into the pocket and the pocket thickened my foot I was indeed able to keep my feet in the pedals better.

Basically, my down kick provided a lot of propulsion, but the recovery stroke was very difficult and felt like it was actively slowing me down. I had of course identified this as a problem before, but this trial has taught me that it is a critical problem.

Things look pretty grim for the success of the Merfluke, because:

At present, my plan is to give my presentation at the Austin Mini-Maker Faire and then abandon this project. I will probably move on to the Solar Cooker in a Public Park project I have written about here.

We cannot expect every project to succeed. Hopefully, we learn something from our failures.

I do not believe that the design space of Thunniform swimming is completely exhausted. That is, I think a better engineer than myself with additional effort might be able to achieve the stated goal of the Merfluke project: to allow a human athlete to swim faster than with a monofin. However, I think the change of this happening is only 10-20%, and I think more benefit will be attained by going on to some other project.

Of course, if anyone disagrees and wants to continue working on this project, you have my blessing, support, and cooperation.

This is a miserable failure; I can probably swim that distance in 15 minutes or less without any fins at at all.

On the bright side, I have invented an effective abdominal exercise machine. :->.

To explain the history of this trial, you may note that my last experiment taught me that despite my attempt to design pedals that would allow me to keep a firm contact with the Merfluke pedals, it didn't work. To correct this, I bought a pair of swim-fins, sawed the fins off the foot pockets with a hacksaw, and used a hot-melt glue gun to glue the foot pockets onto the pedals.

The glue did not work very well. Within 10 minutes I had broken both foot pockets off. However, since my foot was strapped into the pocket and the pocket thickened my foot I was indeed able to keep my feet in the pedals better.

Basically, my down kick provided a lot of propulsion, but the recovery stroke was very difficult and felt like it was actively slowing me down. I had of course identified this as a problem before, but this trial has taught me that it is a critical problem.

Things look pretty grim for the success of the Merfluke, because:

- In order to make it work I have to have the feet securely in the pedals, and

- I previously claimed as an advantage NOT having to have the feet securely in the pedals.

At present, my plan is to give my presentation at the Austin Mini-Maker Faire and then abandon this project. I will probably move on to the Solar Cooker in a Public Park project I have written about here.

We cannot expect every project to succeed. Hopefully, we learn something from our failures.

I do not believe that the design space of Thunniform swimming is completely exhausted. That is, I think a better engineer than myself with additional effort might be able to achieve the stated goal of the Merfluke project: to allow a human athlete to swim faster than with a monofin. However, I think the change of this happening is only 10-20%, and I think more benefit will be attained by going on to some other project.

Of course, if anyone disagrees and wants to continue working on this project, you have my blessing, support, and cooperation.

Wednesday, April 4, 2012

Brief Review of “On Combat”

I recently had the pleasure of finishing: OnCombat: The Psychology and Physiology of Deadly Conflict in War andPeace, by Dave Grossman and Loren W. Christensen.

http://www.amazon.com/On-Combat-Psychology-Physiology-Conflict/dp/0964920514

Obviously, Public Invention has nothing to do with combat. In fact, I eschew the creation of weaponry. I believe mankind needs to focus on the creation of what Buckminster Fuller called “livingry”---inventions which make life better for mankind.Nonetheless, this a great book in and of itself. However, it is also relevant to Public Invention.

Lt. Col. Grossman is creating (along with others) what he calls “warrior science”. This is simply the scientific study of the affect of combat on the warrior, and the warrior on combat. I emphasize scientific because of course since the Iliad and Mahabarata war has been a central theme of mankind's stories. Only recently has the warrior been studied scientifically, leading to insights that can help the warrior both in combat and more importantly after combat. Among the most important realizations of this science are physiological and psychological effects that were previously unexplained and therefore disbelieved, often leading to warriors being treated with shame and incredulity.

Although interesting, I will not recap these important findings here, because they are not relevant. However I invite you to read this excellent book if you are interested in that sort of thing.

What is relevant, however, is that Grossman and others have done and are doing for a different field what I want to do for Public Invention. They have written Warrior Science 101. Perhaps only the first edition, but they have clearly amassed a valuable body of knowledge on the subject.

So, can we do the same for Public Invention? Well, invention is probably harder, because, by definition, it must be new. In 500 BC solving a triangle was a great and innovative achievement, but today it is not. In 1609 BCE a telescope was a great invention, today it is not.

However, we should not let this discourage us. The matter is simply untried at present. There have been studies of creativity. There are studies of genius. I don't think there has been a study of systematic attempts to improve the world by teams of inventors motivated by altruism rather than money.

So I remain hopeful that we can begin “Public Invention 101”, and develop a culture and technology of world changing.

As it happens, I am still waiting for you to join me---so don't be shy. Please comment or promote this blog.

Tuesday, March 27, 2012

No major work this weekend....

However, I have ordered the aluminum for a new set of pedals for the Merfluke. I think I'll try riveting foot pockets on. By building a new complete set of pedals I can do a side-by-side comparison.

I still want to work on the solar-cooker-in-the-park, but I want to give the best presentation I can at the Austin Mini-Maker Faire---and that means I need performance data---and hopefully some that is a little hopeful.

I still want to work on the solar-cooker-in-the-park, but I want to give the best presentation I can at the Austin Mini-Maker Faire---and that means I need performance data---and hopefully some that is a little hopeful.

Subscribe to:

Comments (Atom)

.JPG)