Elliot and I worked on the solar oven again today, without any particularly dramatic results. Nonetheless I summarize the results here.

Note that Elliot invented a very valuable tool for testing our optics, which we call the "green paper test". If you put a sheet of green paper at the aperture, then when looking directly down into the oven you should see a solid glow of green from the entire machine. This is partially true of our best panels to date, as show below.

|

| Green-paper test for our foil-covered poster-board |

Note that foil wrinkles disrupt the solid green pattern and probably cause some inefficiency---but the field of green is still better than that shown below!

As any good scientist should do, we repeated the experiments of that last weekend. That is, using the same apparatus and the same cup of darkened water, we measured the temperature every two minutes. The experiment was performed at 1:00 pm, where where was no danger of the sun not striking a significant face of our darkened water.

Time -- Temperature (Fahrenheit)

0:00 -- 87 F

2:00 -- 143 F

4:00 -- 152 F

6:00 -- 155 F

8:00 -- 159 F

10:00 -- 162 F

12:00 -- 165 F

14:00 -- 170 F

16: 00 -- 172 F

18:00 -- 172 F

This saturation point corresponds to what we measured in the fluid last weekend (after 45 minutes!) once we stuck the tip of the thermometer down in the liquid. So there were no surprises here.

He noted that once removed from the oven, our fluid read a temperature of 143 F in just about 45 seconds. This suggest that our cooking chamber (a Mason jar) does not have very good insulation.

We then sought to reconfirm our wattage by changing to 2 cups of liquid. We carefully covered the oven so that we could uncover it precisely when we began timing, so that we could measure the wattage when the water was cool (before it began losing heat rapidly to ambient environment, as it apparently does at 175 F.) We also switched to once-per-minute measurement.

Here are the results of what I will call the "most careful" experiment:

0:00 -- 90 F

1:00 -- 112 F

2:00 -- 122 F

3:00 -- 128 F

4:00 -- 132 F

5:00 -- 134 F

6:00 -- 138 F

7:00 -- 139 F

8:00 -- 139 F

We are not entirely sure what it means that saturation temperature of a higher amount of water was so much lower, apparently.

We then sought to test if our polished aluminum panels would be better than the aluminum foil. I had polished these panels previously. Unfortunately, they were miscalculated and are cut too narrow, as can be seen in the photographs below. As I've tried to convey in the photographs below, these panels are "mirror-like" but not mirrors. I polished them with a drill that was really too small for the job; compared to a really professional polish they are half-done---yet they reflect an image easily enough for most of their area.

|

| Polished, but imperfect aluminum panel. |

|

| Oven with a few of the panels in place. |

| |

Unfortunately, these panels leaked a lot of light out the sides that should have been reflected to the target, as shown by the "green paper test" and the other photos.

|

| Green paper test of polished, but too-narrow panels. |

|

|

| Leaky machine in the sun, with bright ellipses of light shining through panel seams instead of to target. |

|

| Close up of a leaky seam. |

|

|

The disappointing results of this leaky machine are given below:

0:00 -- 81 F

1:00 -- 83 F

2:20 -- 89 F (note time is 20 seconds out of order, we forgot to measure it!)

3:00 -- 90 F

4:00 -- 93 F

5:00 -- 97 F

6:00 -- 98 F

7:00 -- 99 F

8:00 -- 99 F

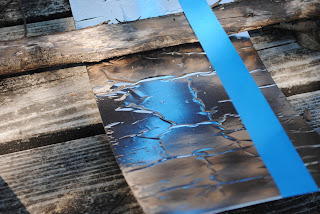

This was a very disappointing result, so we attempted to amend the machine by taping aluminum foil over the seams. Below you can see the mediocre green paper test of our result, showing the crinkly foil there in.

| | | | | | | | | | | |  |

| View taken with flash of our mis-cut panels with foil in place (note foil appears to be ineffective here!) |

|

| Outside version of the green-paper test. |

The results of this measurement were very disappointing---which we interpret to mean that the incorrect geometry trumps the somewhat more specular aluminum. This was again with 2 cups of water.

0:00 -- 80 F

1:00 -- 82 F

2:00 -- 82 F

3:00 -- 97 F

4:00 - 99 F

5:00 -- 100 F

6:00 -- 102 F

7:00 -- 99 F (moved tip of the thermometer here, probably lower

8:00 -- 106 F

9:00 -- 110 F

10:00 -- 112 F

11:00 -- 112 F

12:00 -- 117 F

13:00 -- 114 F

After agitating (stirring) the water, it read 117 F. This suggest that our water is not (at least at low temperatures) all the same temperature in all places. We resolved to agitate the water a bit during future experiments.

We spend the rest of the time building a bracket to hold our new, correctly shaped but unpolished panels in position. In the past we have used hot-melt glue and duct-tape. By pressing downward (quite about, perhaps 6-10 pounds of pressure), the panel can be made to conform well to our parabolic ribs without requiring glue or tape. We hope this system allows us to change panels more effectively in the future.

Our general goal for next weekend is to test our unpolished but properly cut panels, and then to either polish them or cover them with foil and test them again.

One may ask what our goal here is. Basically, we want to build a legitimately well-constructed CPC collector as a baseline. We want to show that we are correctly calculating the wattage of the machine and measuring its efficiency.

Moreover, we want to be able to cook a small amount of meat (that being the typical outdoor usage) with this oven before we contemplate scaling it up to provide higher-wattage overall. We understand of course that with only 100 watts of input (since that is what the sun provides on 1-square foot) we cannot hope to cook something large quickly. However, we want to demonstrate enough concentrated power that it is conveniently short to cook a small amount of meat (say half a hot-dog) before we consider constructing a larger version that might approach what you can get out of typical charcoal barbecue grill.

Tomorrow I will recompute the wattage of our 2-cup experiment to compute our overall efficiency.

* * * (Post scripted)

The formula for converting a change in temperature of dt of a mass m of water in s seconds to power is:

P = (dt * m * 4.18) / s,

where P is in Watts, s is in seconds, m is in grams, and dt in

the change in temperature in Celsius Kelvin. The 4.18 is the number of

Joules in a calorie.

Unfortunately, this suggest that I am either in error or misread the thermometer on the first measurement or that the thermometer did not read the entire mass of the water.

According to the "most careful" experiment, we raised 2 cups (256 grams) of water 22 degrees Fahrenheit, or 12.2 degrees Celsius in only 60 seconds, which comes out to: 217 Watts. Since we believe the solar input on square foot only 100 Watts, I am at a loss to explain this.

I suspect that our thermometer was not giving a true reading of the entire thermal mass of all the water.